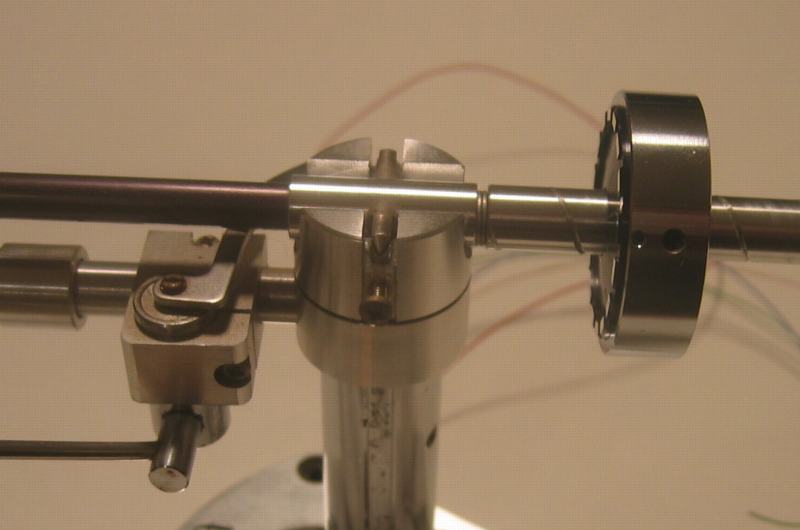

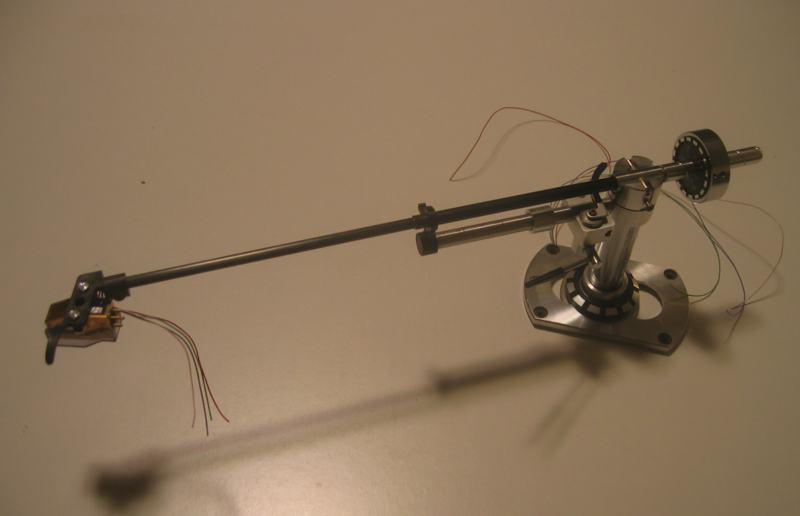

The Black Widow was made by the speaker company Infinity in the mid '70s to early '80s and was a very desireable arm; as a matter of fact, it is considered a classic by many audiophiles to this day. This BW is classified as an ultra-low mass arm and was designed to work with low mass, high compliance moving magnet cartridges. This arm has a double knife edge bearing with a conventional bearing pivot.

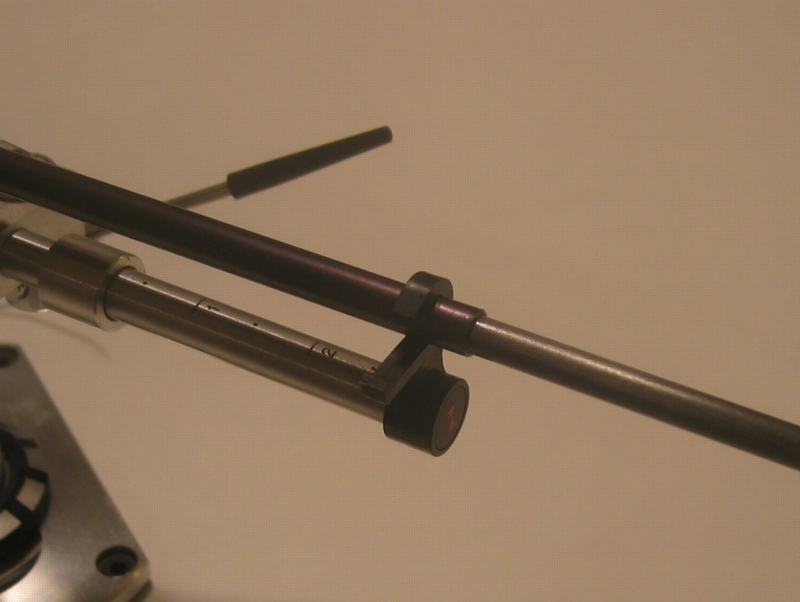

The lore of the Black Widow was that it was the first arm to employ carbon fiber (called graphite in it's day) for it's light weight, high torsoinal strength, and low thermal expansion coefficient. The BW is also said to be somewhat rare, but rare is an overused word these days. There is not a whole lot of solid, factual information on the Black Widow on the internet, so I would like to share through pictures and words what I have learned and how I have rebuilt this little audio gem. I will also try to include closeups and measurements when possible.

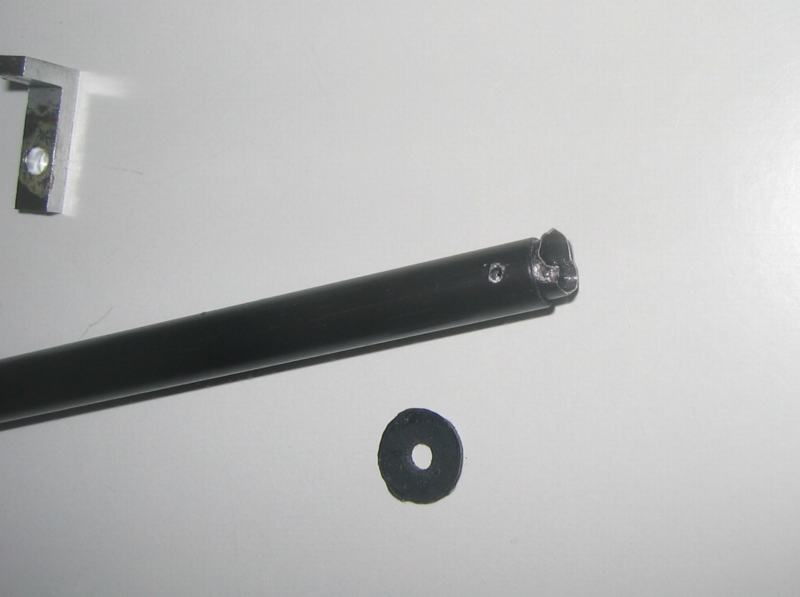

I then thought that the larger tubing was carbon fiber as you could see a bit of grain, but as I popped out the tube retaining pin, a small amount of metal was displaced causing a lump on the edge of the hole - this cannot happen with carbon fiber as it is not malliable. Nope, no carbon. It is almost certain that Infinity would have used this information in their marketing. After a little more searching, I found that the early Black Widow had a two piece aluminum wand while the later model used a one piece carbon fiber wand.

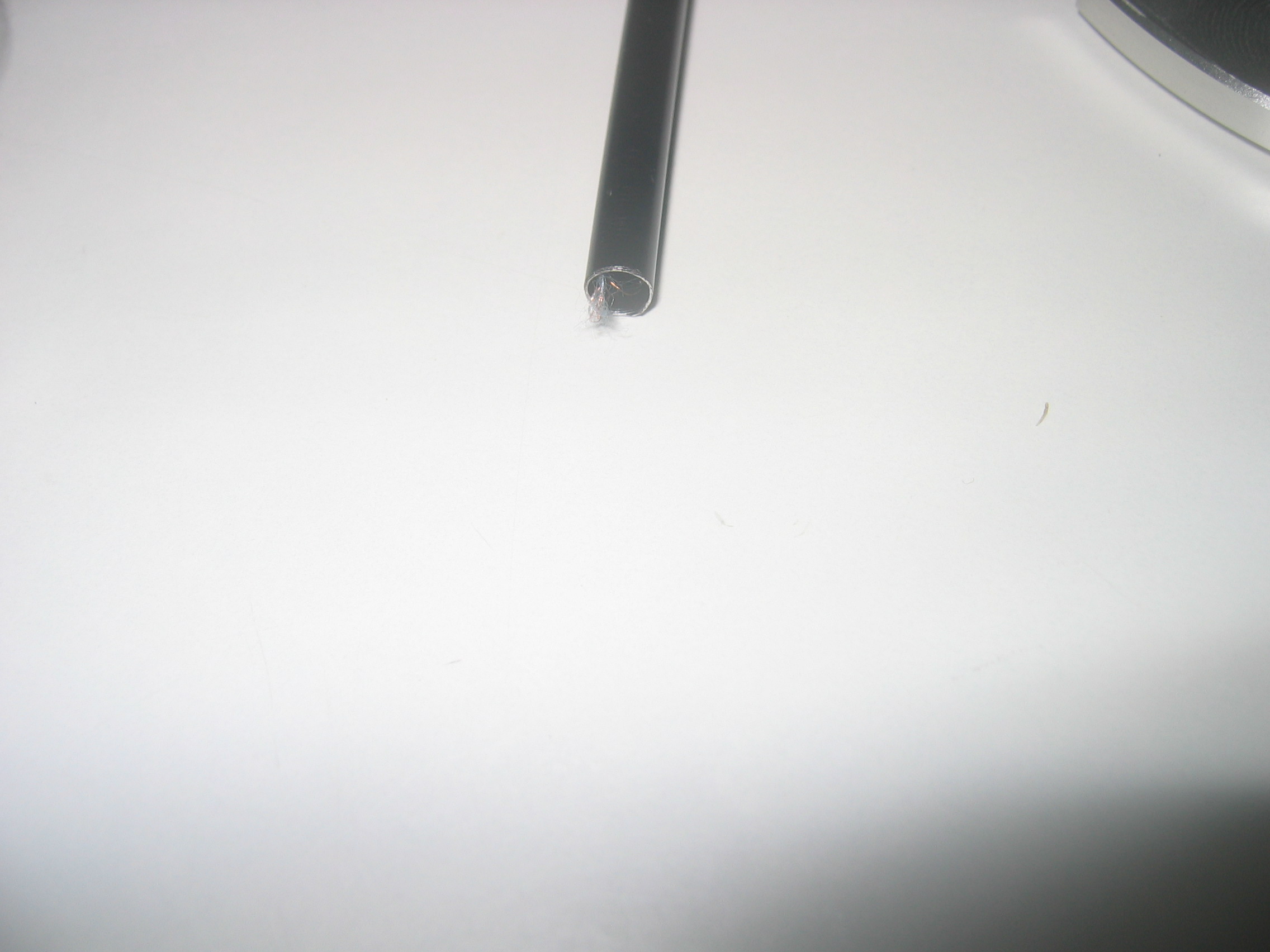

I decided to use carbon fiber to replace the broken arm anyway. Why? Because after searching the net for the few suppliers of thin walled metric aluminum tubing, I would have had to purchase a large and expensive order. I would have also needed to surface mill and anodize to match the outer tubing. That's an awful lot of time and expense. Pulltruded carbon fiber tubing, on the other hand is readily available in a diameter close to what I needed (.180" = 4.58mm), comes in a nice satin black color, and is available one tube at a time. Cool beans.

Page created by James L Woodley © 2006 Page last updated 28 February 2020